Release time:2023-11-12 15:31:41 Hits: Current position: Home > News

This article mainly introduces:

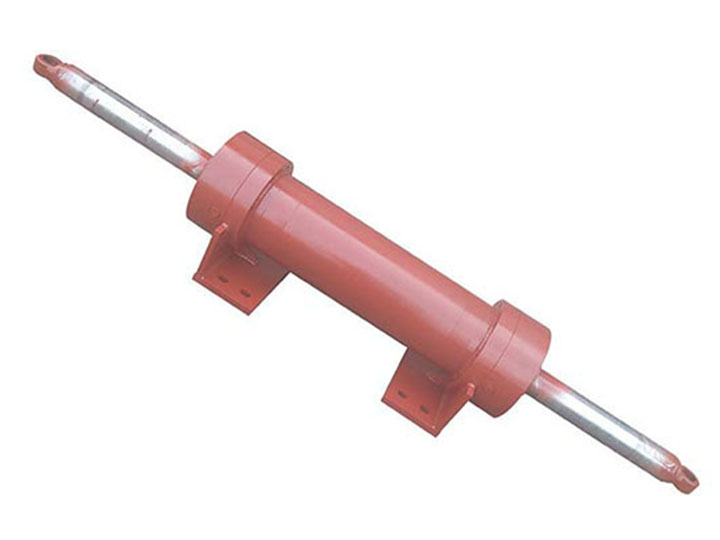

Turkey hydraulic cylinder,track steering cylinder manufacturer,track steering cylinder

(Turkey track steering cylinder,produced by Hengyu Hydraulic Co., Ltd)

track steering cylinder are widely used in Turkey,because of smooth movement,high work efficiency,excellent fatigue and impact resistance.So our company has designed track steering cylinder for customers from Turkey.

The coordination of the sliding parts of the track steering cylinder itself should not be too tight, the sealing friction force should not be too large, and H8 / f8 coordination should be selected between the piston rod and the guide sleeve; Check whether the size of the sealing ring is processed strictly according to the standard; If the V-shaped sealing ring is used, the sealing friction should be adjusted to a moderate degree.

At the rated pressure, the thrust of the track steering cylinder is determined by what factors: at the rated pressure of the oil pump, the work done by the track steering cylinder is related to the diameter of the track steering cylinder, but not to the stroke of the track steering cylinder. Moreover, the larger the track steering cylinder diameter, the larger the area, and the greater the pressure obtained. To this point, we should have a correct understanding and clear understanding, so as to avoid problems in the use of the track steering cylinder.

In the hydraulic system, sometimes the inner layer of the rubber hose is peeled off, so that the oil circuit is on and off, resulting in irregular track steering cylinder action. Troubleshooting method: Replace the rubber hose.

Improve the service life of the track steering cylinder: it is necessary to maintain the normal clearance of the combined surface of the hydraulic components. When manufacturing or repairing the main parts of the track steering cylinder (such as the track steering cylinder block, piston rod, etc.), the assembly should be carried out in accordance with the tolerance lower limit of the assembly size, which can well reduce the occurrence of cavitation. If cavitation has occurred in the hydraulic components, only metallographic sandpaper polishing technology can be used to remove cavitation pitting and surface carbon deposits, and general fine sandpaper must not be used for polishing After the track steering cylinder is repaired, the hydraulic system should run smoothly for a certain period of time so that the hydraulic oil in the hydraulic system can be fully circulated; If necessary, the track steering cylinder inlet pipe (or return pipe) can be disassembled. Make the hydraulic oil overflow to achieve the effect of single track steering cylinder exhaust.

What should we pay attention to when using the cylinder?

When using the cylinder, we should pay attention to the environment and temperature in which it is located as follows: 1. Before working, the hydraulic cylinder must carry out several reciprocating movements under low pressure (greater than the starting pressure), and work normally after removing the gas in the cylinder. 2. Precautions when removing the hydraulic cylinder: ① The pressure in the hydraulic circuit is reduced to zero before disassembly. ② The screw thread at the top of the piston rod should be prevented from damage when disassembling. ③ Due to the different structure and size of the hydraulic cylinder, the order of disassembly is also slightly different. Generally, the fastening bolt of the end cover should be loosened first. Internal card chain card key application special tools.

What are the main technical parameters of the hydraulic cylinder?

Parameters are as follows: 1, cylinder diameter, inner diameter size; 2, import and export diameter and thread parameters; 3, piston rod diameter; 4, cylinder pressure, cylinder working pressure, calculation is often used test pressure, less than 16MPa multiplied by 1.5, higher than 16MPa multiplied by 1.25. 5, cylinder stroke; 6. Is there a buffer? According to the working conditions, the piston rod extension contraction is generally buffered if the impact is large. 7, the installation of the cylinder.