Release time:2023-11-12 15:32:39 Hits: Current position: Home > News

This article mainly introduces:

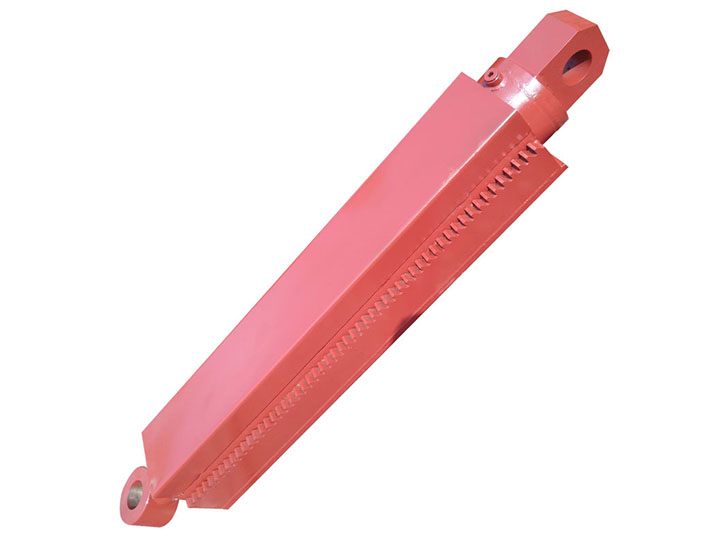

Britain hydraulic cylinder,single rack cylinder manufacturer,single rack cylinder

(Britain single rack cylinder,produced by Hengyu Group)

single rack cylinder are widely used in Britain,because of powerful torque,clever hydraulic energy conversion,simple structure and reliable operation.So our company has designed single rack cylinder for customers from Britain.

The commonly used buffer structure of the single rack cylinder is composed of a piston boss and a single rack cylinder head groove. When the piston moves close to the single rack cylinder head, it gradually enters the groove, and the oil in the groove is extruded through the gap between the boss and the groove, which increases the oil return resistance, produces the braking effect and realizes the buffer. Generally, a buffer mechanism should be used when the pressure is above 10MP.

Repair method of small range wear of oil single rack cylinder: 1. Use oxygen-acetylene flame to bake the scratched part (master the temperature, avoid surface annealing), bake the oil on the metal surface all the year round until no sparks splash; 2. The scratched part is treated with an Angle grinder, the grinding depth is more than 1 mm, and the groove is polished along the guide rail, preferably a dovetail groove. Scratch both ends of the drilling deeper, change the force situation; 3. Clean the surface with absorbent cotton dipped in acetone or anhydrous ethanol.

The internal leakage of the single rack cylinder is an important indicator to measure the quality of the single rack cylinder: the internal leakage of the single rack cylinder will reduce the volumetric efficiency, increase the temperature rise of the oil, affect the positioning accuracy of the single rack cylinder, so that the single rack cylinder can not accurately and stably stop in a certain position of the single rack cylinder, so it is one of the main indicators of the single rack cylinder.

Disassembly single rack cylinder: When disassembly single rack cylinder, strictly prevent damage to the screw thread at the top of the piston rod, the screw thread of the single rack cylinder head and the surface of the piston rod. It should also be noted that the piston cannot be played out from the single rack cylinder.

How do hydraulic equipment and hydraulic cylinders maintain a certain pressure after pressing to a certain position?

There are several methods. 1. You can use a constant pressure variable pump to adjust the control pressure of the pump to the pressure required by the cylinder, so that when the cylinder is in place, the pump uses the minimum flow rate to maintain the pressure, and the system is more energy saving. 2. If the pressure is maintained for a short time, a hydraulic control check valve can be added to the oil inlet end of the cylinder to close the cylinder and maintain the pressure. If the volume of the cylinder is large, an accumulator can be added between the valve and the cylinder to maintain pressure for 10-30 minutes. 3. You can add a small flow pump, the large pump after unloading, the small pump has been running, specifically for maintaining pressure.

What is the difference between hydraulic piston cylinder and plunger cylinder?

The force surface of the piston cylinder is a rod cavity and a rodless cavity, and the force surface of the plunger cylinder is the plunger, the spring return single-acting piston cylinder can also rely on the external force of the spring to achieve return, the double-acting piston cylinder can produce tension, and the plunger cylinder only produces thrust without tension.