Release time:2023-11-13 11:19:06 Hits: Current position: Home > News

This article mainly introduces:

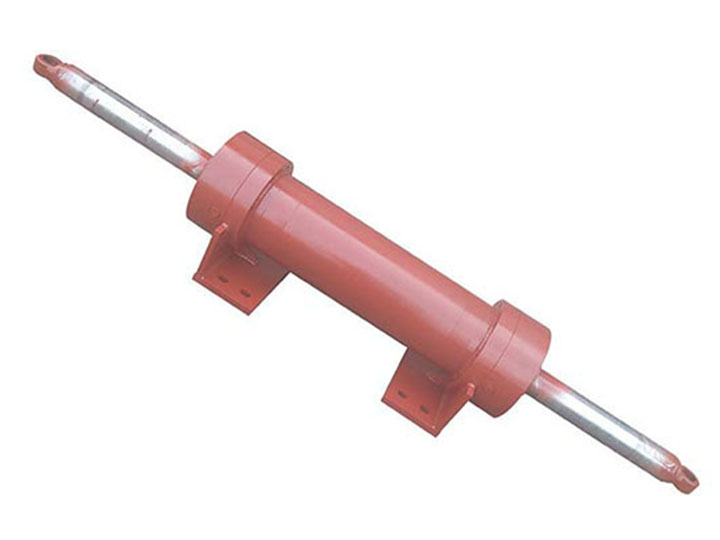

Thailand hydraulic cylinder,track steering cylinder manufacturer,track steering cylinder

(Thailand track steering cylinder,produced by Hengyu Hydraulic Cylinder Factory)

track steering cylinder are widely used in Thailand,because of long service life,smooth movement,high work efficiency.So our company has designed track steering cylinder for customers from Thailand.

If the track steering cylinder is sliding or crawling (stop and go), check whether there is any astringency inside the track steering cylinder. The internal parts of the track steering cylinder are improperly assembled, the parts are deformed, worn or the shape and position tolerance is excessive, and the action resistance is too large, so that the piston speed of the track steering cylinder changes with the different stroke position, and there is slip or crawl. Most of the reasons are due to poor assembly quality of parts, surface scars or sintered iron filings, so that the resistance increases, the speed decreases. For example, the piston is different from the piston rod or the piston rod is bent, the track steering cylinder or the piston rod is offset from the mounting position of the guide rail, and the sealing ring is too tight or too loose. The solution is to repair or adjust, replace damaged parts and remove iron filings. At the same time, check whether the lubrication is good or whether the track steering cylinder bore processing is out of whack. Because the piston and track steering cylinder, guide rail and piston rod are relative If the track steering cylinder is crawling seriously, check whether air has entered the hydraulic system. Air compression or expansion can cause the piston to slip or crawl. The exclusion measures are to check the hydraulic pump, set up a special exhaust device, and quickly operate the exhaust several times in the full stroke. Check the seals at the same time, because the quality of the seals is directly related to slippage or crawling. When the O-ring is used under low pressure, compared with the U-ring, it is easy to slip or crawl because of the higher surface pressure and the larger difference between static and static friction resistance. The surface pressure of the U-shaped sealing ring increases with the increase of pressure, although the sealing effect is correspondingly improved, but the difference between static and static friction resistance is also larger, the internal pressure increases, affecting the rubber elasticity, due to the increase in the contact resistance of the lip, the sealing ring will tip over and the lip elongation, and it is also easy to cause slip or crawling track steering cylinder weight composition and calculation. The weight of the track steering cylinder is composed of the track steering cylinder diameter, the outer diameter and weight of the track steering cylinder, the rod diameter, and the weight of the accessories, so in calculation, it is to add all these together to get the specific value. However, if there are special circumstances, it may be calculated separately. This work can be carried out by yourself, but it can also be carried out by professionals, so that mistakes can be avoided.

The daily inspection of the track steering cylinder includes: checking the connection of the track steering cylinder and the pipe joint for leaks. Check the track steering cylinder rod for leaks. Check the track steering cylinder connection for leaks. When the track steering cylinder moves, the work is normal and smooth. Whether the track steering cylinder has internal leakage.

The method of sleeve track steering cylinder to improve the processing quality: there is a big gap in the service life of post-plating polishing and post-plating polishing, especially in mass production. Strictly clean the flying edge and burr of mechanical components, especially the edge of the sealing groove, and the tiny metal burr, strictly clean before assembly. The surface fatigue strength and stress corrosion resistance of the track steering cylinder can be significantly improved by rolling in the finishing of the inner holes of the track steering cylinder. The roughness of the surface of the friction pair is generally controlled between Ra0.4 and 0.8.

The pressure of the sliding surface of the track steering cylinder piston is too large, resulting in sintering. The piston tilts due to the weight of the piston rod, resulting in the phenomenon of non-stiffness, or the pressure of the sliding surface of the piston rises due to the action of the transverse load, which will cause sintering. In the design of the track steering cylinder must study its working conditions, the length of the piston and bushing and the size of the clearance must be fully paid attention to.

What is the HS code of the hydraulic cylinder?

HS code of hydraulic cylinder; 8412210000 8412210000 Linear hydraulic power unit (hydraulic cylinder) 0.12000 0.35000 0.00000 0.17000 0.00000

How does the one-way solenoid valve control the hydraulic cylinder circuit?

If your cylinder is single-acting, you can use a one-way solenoid valve, such as some lifting platform hydraulic cylinder, the support valve used is one-way (two-position tee), that is, the cylinder extends out by the oil pressure top, the cylinder retracted by its own weight.