Release time:2023-11-21 09:56:11 Hits: Current position: Home > News

This article mainly introduces:

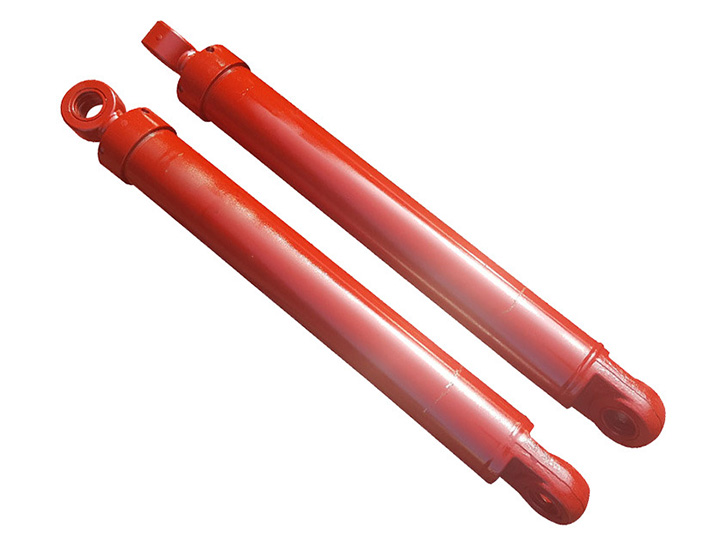

America hydraulic cylinder,stacker cylinder manufacturer,stacker cylinder

(America stacker cylinder,produced by Hengyu Hydraulic Co., Ltd)

stacker cylinder are widely used in America,because of smooth movement,high work efficiency,excellent fatigue and impact resistance.So our company has designed stacker cylinder for customers from America.

The stacker cylinder should not be mixed with foreign objects during assembly, which will cause scars. Before the total assembly of the stacker cylinder, all parts must be fully removed and cleaned. When the parts are installed with burrs or dirt, foreign objects are easily embedded into the surface of the stacker cylinder wall due to the stiffness and the weight of the parts, causing scars.

In recent years, the processing process of the stacker cylinder generally adopts the rolling method, which is a pressure finishing processing, which uses the cold plastic characteristics of the metal at room temperature, and uses the rolling tool to exert a certain pressure on the surface of the workpiece, so that the surface metal of the workpiece produces plastic flow, and fills in the low concave trough of the original residue, and the roughness value of the workpiece surface is reduced. Due to the plastic deformation of the rolled surface metal, the surface tissue is cold hardened and the grain is fine, forming a dense fiber, and forming a residual stress layer, and the hardness and strength are increased, thus improving the wear resistance, corrosion resistance and compatibility of the workpiece surface. Rolling is a plastic machining method without cutting.

The stacker cylinder pipe should not be left behind when deburring at both ends after the fixed length processing. In addition, the placement of steel pipes near the site of welding pipeline operations is the cause of welding foreign objects. The pipes placed near the welding operation site should be sealed. It must also be noted that pipe fitting materials should be fully prepared on a dust-free workbench.

The difference between the integral stacker cylinder and the split stacker cylinder: The integral stacker cylinder and the split stacker cylinder in the stacker cylinder are two different stacker cylinders, and they are very different. The whole stacker cylinder, which is cast in one body, is not prone to problems such as oil leakage; The split stacker cylinder is welded twice, so if it is not handled well at the welding, it is prone to problems such as oil leakage and stacker cylinder damage. Therefore, it is obvious that the answer to this question is for difference.

How big gear pump need to use for 60*100 cylinder?

One cylinder size alone does not determine the size of the pump used. Choose the size of the pump, at least to know 1, the size of the load is how much, by the size of the load and the size of the cylinder and other conditions can be calculated the pressure required by the hydraulic system. 2. Speed of operation. From this speed and cylinder size, the required flow rate of the system is calculated. The relevant parameters of the pump can be selected by the pressure and flow rate to determine what kind of pump is required.

Why does the hydraulic cylinder not return?

For a spring return cylinder, it is possible that 1, the spring is damaged. You can check it for processing. 2, the oil in the oil path is not unloaded, causing it to be unable to reset. 3, the cylinder piston is dead, resulting in no position. For double-acting cylinders, it is possible to: 1, the spool is not reversed, or is not changed to the correct position, check whether the reversing valve is normal (and whether there is electricity). 2, the cylinder piston is dead, resulting in no position, check and treatment can be. 3, the return oil pressure is insufficient, the inlet oil is not unloaded, the operation is not smooth. For reference only.