Release time:2023-12-09 16:24:26 Hits: Current position: Home > News

This article mainly introduces:

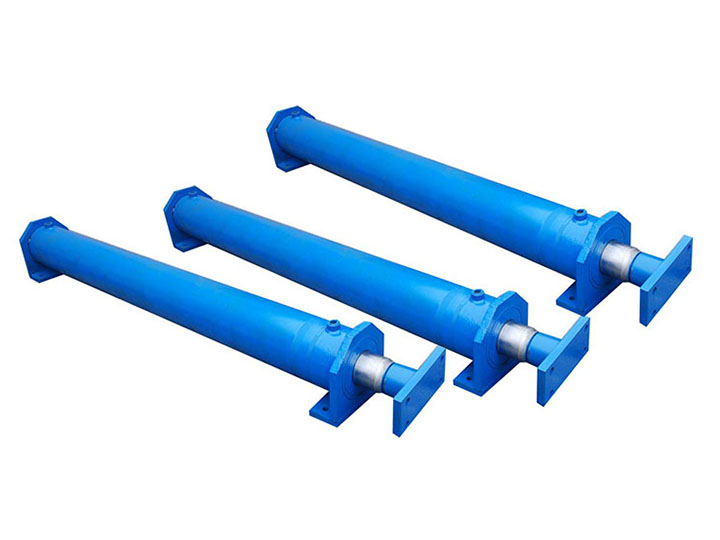

Nigeria hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(Nigeria push and pull the cylinder,produced by Hebei Hengyu company)

push and pull the cylinder are widely used in Nigeria,because of clever hydraulic energy conversion,simple structure and reliable operation,excellent temperature resistance.So our company has designed push and pull the cylinder for customers from Nigeria.

When installing the piston rod, it is necessary to ensure that the direction of the connecting head at the top of the piston rod should be consistent with the direction of the push and pull the cylinder head adn the earring (or the middle hinge shaft), and ensure the straightness of the whole piston rod during the advance and return process to prevent the phenomenon of rigid interference and causing unnecessary damage.

The repair method of push and pull the cylinder wear: 1. Metal repair material is applied to the scratched surface; The first layer should be thin, uniform and fully covered with the scratched surface to ensure the best adhesion between the material and the metal surface, and then apply the material to the entire repair site and press repeatedly to ensure that the material is filled and reaches the required thickness, so that it is slightly higher than the surface of the guide rail; 2, the material at 24℃ to fully achieve the performance of 24 hours, in order to save time, can be through the tungsten halogen lamp to increase the temperature, the temperature rises 11℃, the curing time will be reduced by half, the best curing temperature 70℃; 3. After the material is cured, use a fine grinding stone or a scraper to repair and smooth the material higher than the surface of the guide rail, and the construction is completed.

When the control pressure of the hydraulic system is too low, the push and pull the cylinder will appear wrong or no action, because the throttle resistance in the control pipeline may be too large, the flow valve is improperly adjusted, the control pressure is inappropriate, and the pressure source is interfered with. At this time, check the control pressure source to ensure that the pressure is adjusted to the specified value of the system.

push and pull the cylinder is the most important part of construction machinery, the traditional processing method is: broaching push and pull the cylinder block - fine boring push and pull the cylinder block - grinding push and pull the cylinder block. The rolling method is: broaching push and pull the cylinder block - fine boring push and pull the cylinder block - rolling push and pull the cylinder block, the process is 3 parts, but the time is compared: grinding 1 meter of the push and pull the cylinder block is about 1-2 days, rolling 1 meter of the push and pull the cylinder block is about 10-30 minutes. Input comparison: grinding machine or quilting machine (tens of thousands - millions), rolling knife (ten thousand - tens of thousands). After rolling, the surface roughness of the hole decreases from RA3.2-6.3 μm before rolling to Ra0.4 ~ 0.8μm, the surface hardness of the hole increases by about 30%, and the fatigue strength of the inner surface of the push and pull the cylinder increases by 25%. If the push and pull the cylinder life is only considered, it is increased by 2 to 3 times, and the boring and rolling process is 3 times more efficient than the grinding process In particular, if you want to make high-quality push and pull the cylinders, you must take the rolling production process. After the push and pull the cylinder is rolled, there is no sharp tiny edge on the surface, and long-term motion friction will not damage the seal ring or seal, which is particularly important in the hydraulic industry.

By what means can the hydraulic system control the arbitrary stroke position of the rotary cylinder piston rod?

The following ways can be considered: 1, through the limit device, such as limit switch, position sensor, etc. 2, by feedback the pressure of the hydraulic oil in the cylinder. The load determines the pressure, the pressure in the cylinder is determined by the load, and the pressure is very small when the cylinder is unloaded. 2.1 When clamping the workpiece, the pressure of the cylinder increases, by calculating the relationship between the clamping force and the pressure of the cylinder, take a pressure value of the cylinder, set the pressure switch, and drive the valve to work when the pressure reaches the preset value, so that the oil circuit stops supplying oil. 2.2 or set the pressure value of the relief valve to overflow after a certain set pressure.

Does the sealing string of the upper and lower chamber of the hydraulic cylinder fall by itself?

It is possible, the probability accounts for 85% (depending on the weight), the weight is less than the system resistance, may not fall, the weight is greater than the system resistance, will not necessarily fall, so often check the equipment, safety first, find the problem in time to solve, the cylinder is not very expensive parts, maintenance does not cost much money, However, accidents caused by cylinder failure will lose several times the cost.