Release time:2023-12-12 10:13:46 Hits: Current position: Home > News

This article mainly introduces:

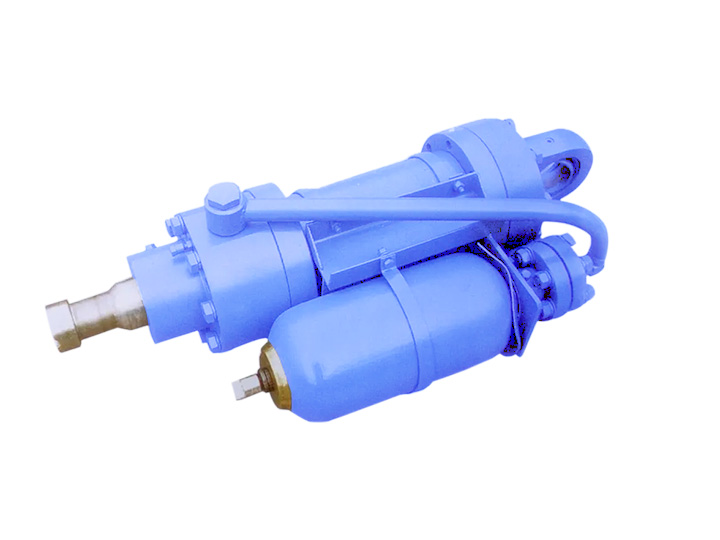

Qatar hydraulic cylinder,accumulator hydraulic cylinder manufacturer,accumulator hydraulic cylinder

(Qatar accumulator hydraulic cylinder,produced by Hengyu Group)

accumulator hydraulic cylinder are widely used in Qatar,because of simple structure and reliable operation,excellent temperature resistance,no transmission clearance.So our company has designed accumulator hydraulic cylinder for customers from Qatar.

The cavitation of the accumulator hydraulic cylinder has a great influence, and to avoid it, it is necessary to use the hydraulic oil reasonably and ensure the quality of the hydraulic oil. If the anti-foam property of the oil is poor, it is easy to produce foam, resulting in cavitation. Secondly, the change frequency of oil pressure is too fast and too high, which will also directly cause the formation of bubbles and accelerate the rupture rate of bubbles. The test shows that the speed of cavitation will be accelerated in the part with high frequency of pressure change. For example, at the inlet and outlet of the accumulator hydraulic cylinder, due to the relatively high frequency of pressure changes, the degree of cavitation is also relatively higher than that of other parts. In addition, overheating of the oil will also increase the probability of cavitation.

accumulator hydraulic cylinder body inspection: The inner surface of the accumulator hydraulic cylinder and the piston seal are the main factors causing the leakage in the accumulator hydraulic cylinder, if the accumulator hydraulic cylinder has a longitudinal tensile mark, even if the new piston seal is replaced, it can not effectively eliminate the fault, the inner surface of the accumulator hydraulic cylinder mainly checks whether the dimensional tolerance and shape and position tolerance meet the technical requirements, there is no longitudinal tensile mark, and measures the depth of the longitudinal tensile mark, in order to take the corresponding solution.

The wear of the hard chromium plating layer of the accumulator hydraulic cylinder is mostly caused by the grinding of the friction iron powder of the piston, and the wear is faster when there is water in the middle. Corrosion caused by the contact potential difference of the metal only occurs in the part of the piston contact, and the corrosion occurs in a point pattern. As mentioned above, when there is moisture in the middle, it will promote the development of corrosion. Compared with castings, the contact potential difference of copper alloy is higher, so the corrosion degree of copper alloy is more serious.

accumulator hydraulic cylinder is the most important part of construction machinery, the traditional processing method is: broaching accumulator hydraulic cylinder block - fine boring accumulator hydraulic cylinder block - grinding accumulator hydraulic cylinder block. The rolling method is: broaching accumulator hydraulic cylinder block - fine boring accumulator hydraulic cylinder block - rolling accumulator hydraulic cylinder block, the process is 3 parts, but the time is compared: grinding 1 meter of the accumulator hydraulic cylinder block is about 1-2 days, rolling 1 meter of the accumulator hydraulic cylinder block is about 10-30 minutes. Input comparison: grinding machine or quilting machine (tens of thousands - millions), rolling knife (ten thousand - tens of thousands). After rolling, the surface roughness of the hole decreases from RA3.2-6.3 μm before rolling to Ra0.4 ~ 0.8μm, the surface hardness of the hole increases by about 30%, and the fatigue strength of the inner surface of the accumulator hydraulic cylinder increases by 25%. If the accumulator hydraulic cylinder life is only considered, it is increased by 2 to 3 times, and the boring and rolling process is 3 times more efficient than the grinding process In particular, if you want to make high-quality accumulator hydraulic cylinders, you must take the rolling production process. After the accumulator hydraulic cylinder is rolled, there is no sharp tiny edge on the surface, and long-term motion friction will not damage the seal ring or seal, which is particularly important in the hydraulic industry.

Why hydraulic cylinder load can not rise?

The hydraulic cylinder does not top up indicates that the pressure of the working chamber of the hydraulic cylinder is insufficient, and the following circumstances can lead to insufficient pressure: 1) The relief valve of the hydraulic system cannot establish pressure, elimination method: check whether the pressure setting screw of the relief valve is screwed to the appropriate position. If it is an electromagnetic relief valve, please check the power-on condition. 2) The hydraulic system pipeline is connected incorrectly, when P and T are connected, this must be checked and excluded; 3) Excessive leakage in the hydraulic cylinder, resulting in (only for double-acting cylinders); 3) No hydraulic oil into the working chamber of the hydraulic cylinder, elimination method: first disassemble the hydraulic pipe connecting the reversing valve and the hydraulic cylinder, and then control the reversing valve, and observe whether there is hydraulic oil flowing out of the reversing valve.

How long can a hydraulic cylinder work continuously?

If the maintenance is good, the service life can be extended a lot. The life of the cylinder is related to the structure of the cylinder, working pressure, stress state, hydraulic oil cleanliness, oil temperature control, maintenance and preventive measures. For example, the cylinder structure, the inner wall of the cylinder has quilting, rolling, chrome plating and other methods, the sealing parts have polyurethane rings, glay rings, metal sealing rings, etc., different combinations, the life difference is dozens of times. Metallurgical system is a typical cylinder application, in 24 hours of work, a year or more can not be shut down, in the middle of continuous work.