Release time:2023-11-12 15:25:52 Hits: Current position: Home > News

This article mainly introduces:

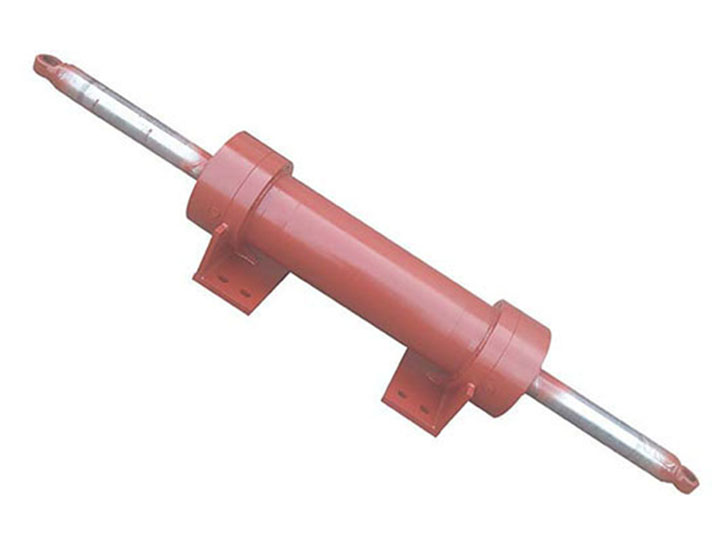

Turkmenistan hydraulic cylinder,vehicle hydraulic cylinder manufacturer,vehicle hydraulic cylinder

(Turkmenistan vehicle hydraulic cylinder,produced by Hebei Hengyu company)

vehicle hydraulic cylinder are widely used in Turkmenistan,because of excellent temperature resistance,no transmission clearance,powerful torque.So our company has designed vehicle hydraulic cylinder for customers from Turkmenistan.

The main role of the vehicle hydraulic cylinder: the vehicle hydraulic cylinder is an executive element in the hydraulic transmission system, which is an energy conversion device that converts hydraulic energy into mechanical energy. The hydraulic motor realizes continuous rotary motion, while the vehicle hydraulic cylinder realizes reciprocating motion. The structure of the vehicle hydraulic cylinder has three categories: piston vehicle hydraulic cylinder, plunger vehicle hydraulic cylinder, swing vehicle hydraulic cylinder, piston vehicle hydraulic cylinder and plunger vehicle hydraulic cylinder to achieve reciprocating linear motion, output speed and thrust, swing vehicle hydraulic cylinder to achieve reciprocating swing, output angular speed (speed) and torque. In addition to the single use of the vehicle hydraulic cylinder, two or more can be combined or used in combination with other mechanisms. To fulfill a special function. The vehicle hydraulic cylinder has simple structure and reliable operation, and has been widely used in the hydraulic system of machine tools.

If air enters the hydraulic system, the vehicle hydraulic cylinder will not operate normally, mainly because there is a leak in the system. At this time, check the liquid level of the hydraulic tank, the seals and fittings on the oil suction side of the hydraulic pump, and whether the oil suction filter is too dirty. If so, the hydraulic oil should be replenished, seals and fittings should be treated, and the coarse filter element should be cleaned or replaced.

The repair method of the vehicle hydraulic cylinder: the repair of the vehicle hydraulic cylinder must use brush plating. This is because this repair method can be carried out on site, and the repair effect is good. In this way, loading and transportation can be eliminated to shorten the repair time and improve work efficiency. In addition, the coating obtained by brush plating has good binding force and will not have obvious boundaries. Moreover, the repair surface has high hardness and good wear resistance.

When the vehicle hydraulic cylinder is customized, if there are high requirements for the quality of the vehicle hydraulic cylinder, it is best to use rolling processing, because the surface layer has surface residual compressive stress, which helps to close the surface of the small crack, preventing the expansion of erosion. Thus, the corrosion resistance of the surface can be improved, and the fatigue crack can be delayed or expanded, and the fatigue strength of the vehicle hydraulic cylinder can be improved. By rolling forming, a cold working hardening layer is formed on the rolling surface, which reduces the elastic and plastic deformation of the contact surface of the grinding pair, thereby improving the wear resistance of the inner wall of the vehicle hydraulic cylinder and avoiding the burn caused by grinding. After rolling, the reduction of surface roughness value can improve the matching property.

Hydraulic cylinder performance requirements?

Hydraulic cylinder performance requirements: hydraulic cylinder is the hydraulic system to achieve energy transfer, conversion and control of the working medium, in addition, it is also responsible for the lubrication of the system, rust prevention, corrosion prevention and cooling. The performance of hydraulic oil will make the system flexible, accurate and reliable. Hydraulic performance requirements are determined according to the design parameters of the hydraulic system, operating conditions, the structure of the hydraulic pump and the working environment. Appropriate viscosity and good viscosion-temperature performance Viscosity is an important performance indicator of hydraulic pressure, which has an important impact on the smooth operation of the hydraulic system and the friction parts. The low temperature performance of hydraulic oil includes three aspects: low temperature flow, low temperature start-up and low temperature pumping.

What hydraulic oil does servo cylinder generally use?

The medium used by the cylinder generally depends on the working condition of the use, including pressure, installation environment, sealing material, etc. I think the first thing to consider is the impact of the sealing material. Mineral oil is a good choice if it is not too fire-resistant or used in a high temperature environment. 1, servo cylinder features: closed-loop servo control, control accuracy of 0.01mm; Precise control of thrust, increase pressure sensor, control accuracy up to 1%; It is easy to connect with PLC and other control systems to achieve high precision motion control. Low noise, energy saving, clean, high rigidity, impact resistance, long life, simple operation and maintenance. 2, the servo cylinder can be fault-free in harsh environments, and the protection level can reach IP66.